YCM-25 Next-Gen Frameless Hollow-Shaft Stator-Rotor Assemblies

Industry-leading torque density and superior adaptability for seamless drive integration. Frameless: Flexible design for diverse setups. High torque density: Powerful, cost-effective. Hollow-shaft: Versatile installation/integration. Lightweight & compact: Space/weight-saving. Low-voltage: 12V–48V, safe/efficient. Optimized copper fill: High torque, dynamic performance. Concentrated coils: Low thermal loss, efficient/durable. Thermally optimized: Reliable under demand. Tailored systems: Weight/space-saving via load analysis. Precise control: Accurate, responsive. Broad compatibility: Adapts to diverse needs.

Within 10:

Within 50:

From 51+: Contact us for best price

Delivery time: 7-15 DAYS

Retail Price 122 USD

Market price 128 USD

库存剩余 100

隐藏域元素占位

- DESCRIPTION

- SPECIFICATIONS

- 3D

- ORDERING INFORMATION

-

- Commodity name: YCM-25 Next-Gen Frameless Hollow-Shaft Stator-Rotor Assemblies

Industry-leading torque density and superior adaptability for seamless drive integration. Frameless: Flexible design for diverse setups. High torque density: Powerful, cost-effective. Hollow-shaft: Versatile installation/integration. Lightweight & compact: Space/weight-saving. Low-voltage: 12V–48V, safe/efficient. Optimized copper fill: High torque, dynamic performance. Concentrated coils: Low thermal loss, efficient/durable. Thermally optimized: Reliable under demand. Tailored systems: Weight/space-saving via load analysis. Precise control: Accurate, responsive. Broad compatibility: Adapts to diverse needs.

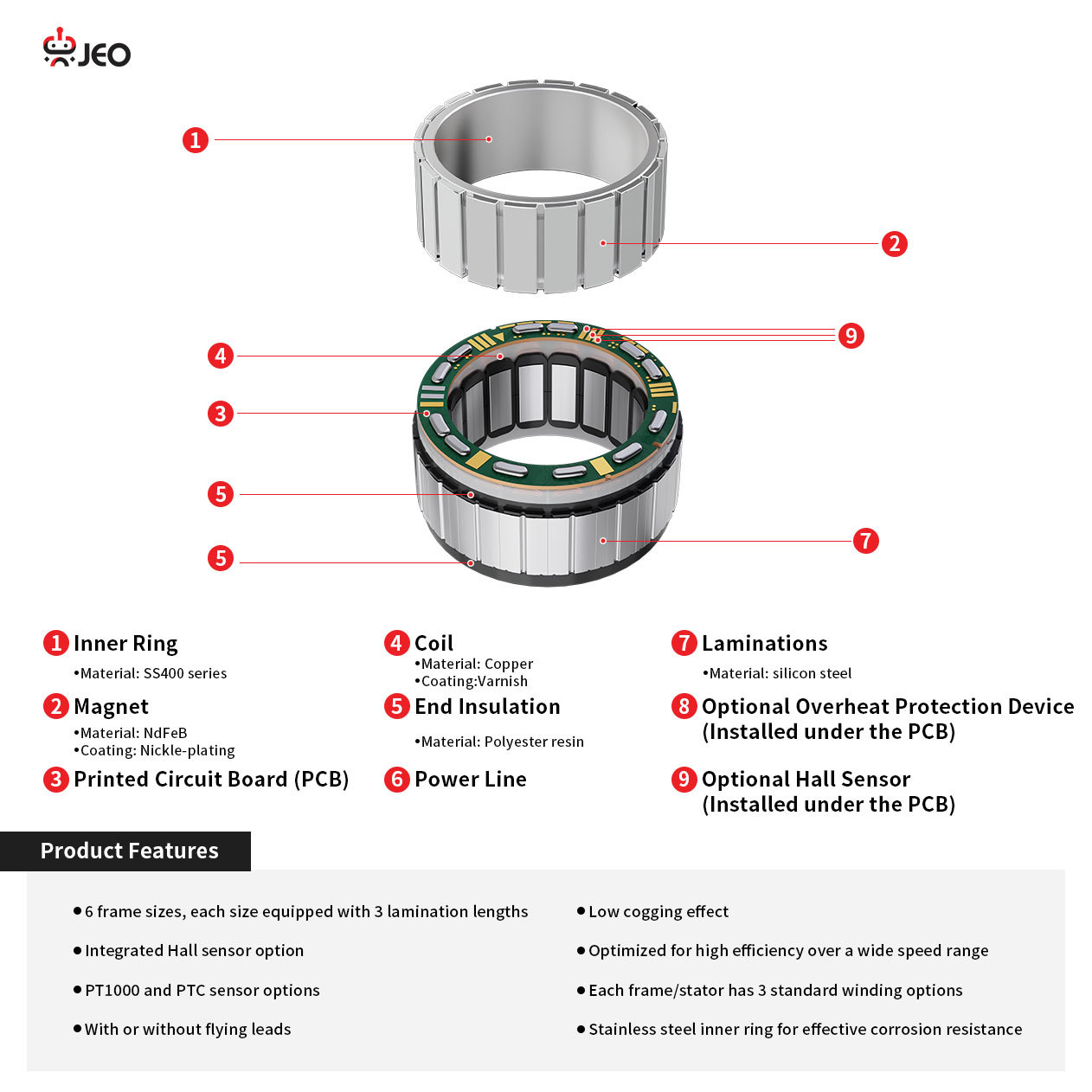

Jeomotor’s stator and rotor assemblies are precision magnetic drive components engineered for high‑torque, high‑efficiency motion systems. These frameless, hollow‑shaft stator‑rotor units provide excellent torque density, low thermal loss, and reliable performance in robotics and automation applications.

Introduction to Frameless Motor

Frameless motor is a highly integrated motor design that differs from traditional motors,

It omits the external casing and bearing structure, consisting only of two parts: the rotor component (magnetic steel+iron core) and the stator component (winding+iron core).

This design allows it to be directly embedded into the mechanical structure of the equipment, achieving a more compact and lightweight system layout through "mechatronics integration".

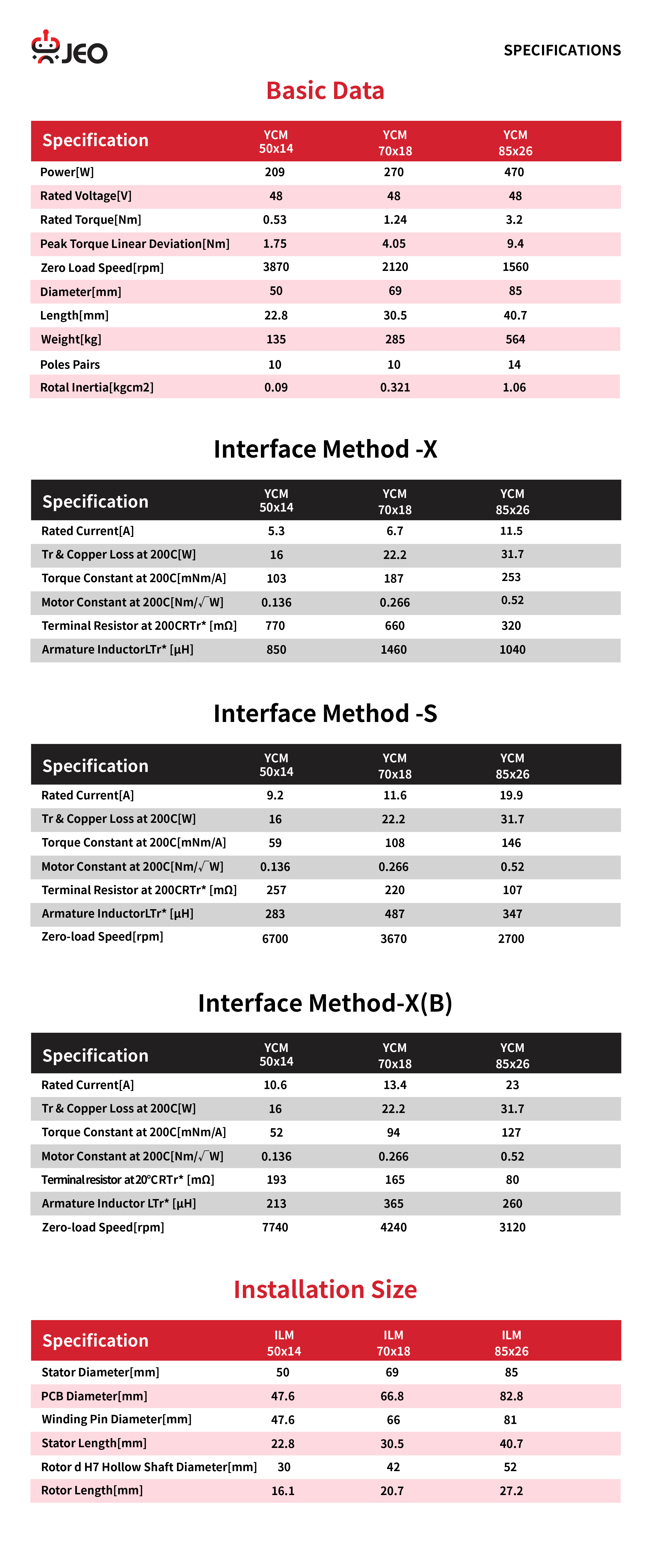

Core parameters:

-Torque density: 5-30 Nm/kg (varies depending on the magnetic steel material and cooling method)

-Speed range: 500-20000 RPM (supports high-speed precision control)

-Power density: 1-5 kW/kg (more than 30% higher than traditional framed motors)

-Thermal management: relying on external cooling system, the operating temperature is usually ≤ 125 ℃Structural features:

1. Rotor: High performance permanent magnets (such as neodymium iron boron) are used, which are directly fitted onto the load shaft and fixed by interference fit or adhesive.

2. Stator: Without frame support, the winding is directly embedded in the equipment base and requires customized heat dissipation channels (such as water cooling slots).

3. Feedback system: Integrated high-resolution encoder (such as 17 bit absolute value encoder) to achieve micrometer level positioning accuracy.Core advantages:

-Lightweight: eliminating redundant structures, reducing weight by 40% -60%

-High rigidity: The rotor is directly connected to the load shaft, eliminating transmission clearance and improving dynamic response

-Flexible customization: adaptable to irregular spaces, supporting multi axis parallel or hollow axis designApplication scenarios:

-Industrial field: Collaborative robot joints, CNC machine tool spindles, semiconductor wafer positioning platforms

-Aerospace: Flight control servos, satellite antenna drive mechanisms

-Medical equipment: surgical robots, MRI scanners, rotating parts

-New energy: electric drive system (wheel hub motor, electric spindle)Usage method:

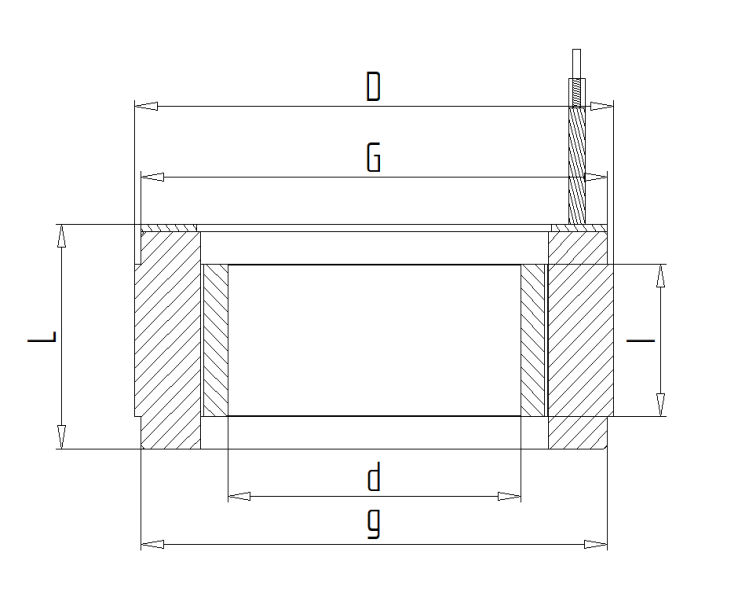

1. Mechanical integration: Directly press fit the rotor onto the load shaft (with controlled interference of ≤ 0.02mm), fix the stator on the equipment base and ensure uniform air gap (± 0.03mm).

2. Thermal management: When forced cooling (such as circulating water cooling), it is necessary to seal and prevent leakage, and air cooling should reserve airflow channels.

3. Control matching: Low harmonic drivers are required to suppress cogging torque fluctuations and set over temperature/overload protection.The frameless motor improves efficiency to over 97% by eliminating losses in the mechanical transmission chain, making it particularly suitable for high-end equipment fields with strict requirements for space, weight, and dynamic performance,It is an ideal choice for intelligent manufacturing and precision drive systems.

Highlights

1. Revolutionary structural design

▪ Adopting frameless direct drive architecture, supporting full modular combination (integrated safety brake+encoder hollow shaft)▪ Ultra wide voltage compatibility (12v-48vDC) to meet the requirements of complex working conditions

▪ Breakthrough magnetic circuit optimization technology, achieving axial space savings of over 40%.

2. Ultimate Performance

▪ Relying on high slot full rate winding technology (copper filling coefficient>85%), the torque density reaches the industry benchmark of 35Nm/kg

▪ Thermal optimization cycle heat dissipation channel, continuous torque output capacity increased by 50%

3. Customized engineering capability

▪ Provide a fully configurable design platform (pole pairs/winding methods/installation interfaces), Instantaneous overload capacity reaches 300% of rated torque

▪ Customizable according to customer needs

Note:

The thermal performance is closely related to the installation environment, and the rated working temperature is -40 ℃~125 ℃.

Theoretical no-load speed of rated voltage Ur; The use of different transformers may vary.

The maximum speed depends on the mechanical structure. -

-

Delivery time: 7-12 days

| Downloads

| Product Inquiry

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

With technological innovation as the core and quality management as the foundation, we are committed to providing customers with high-quality products and services