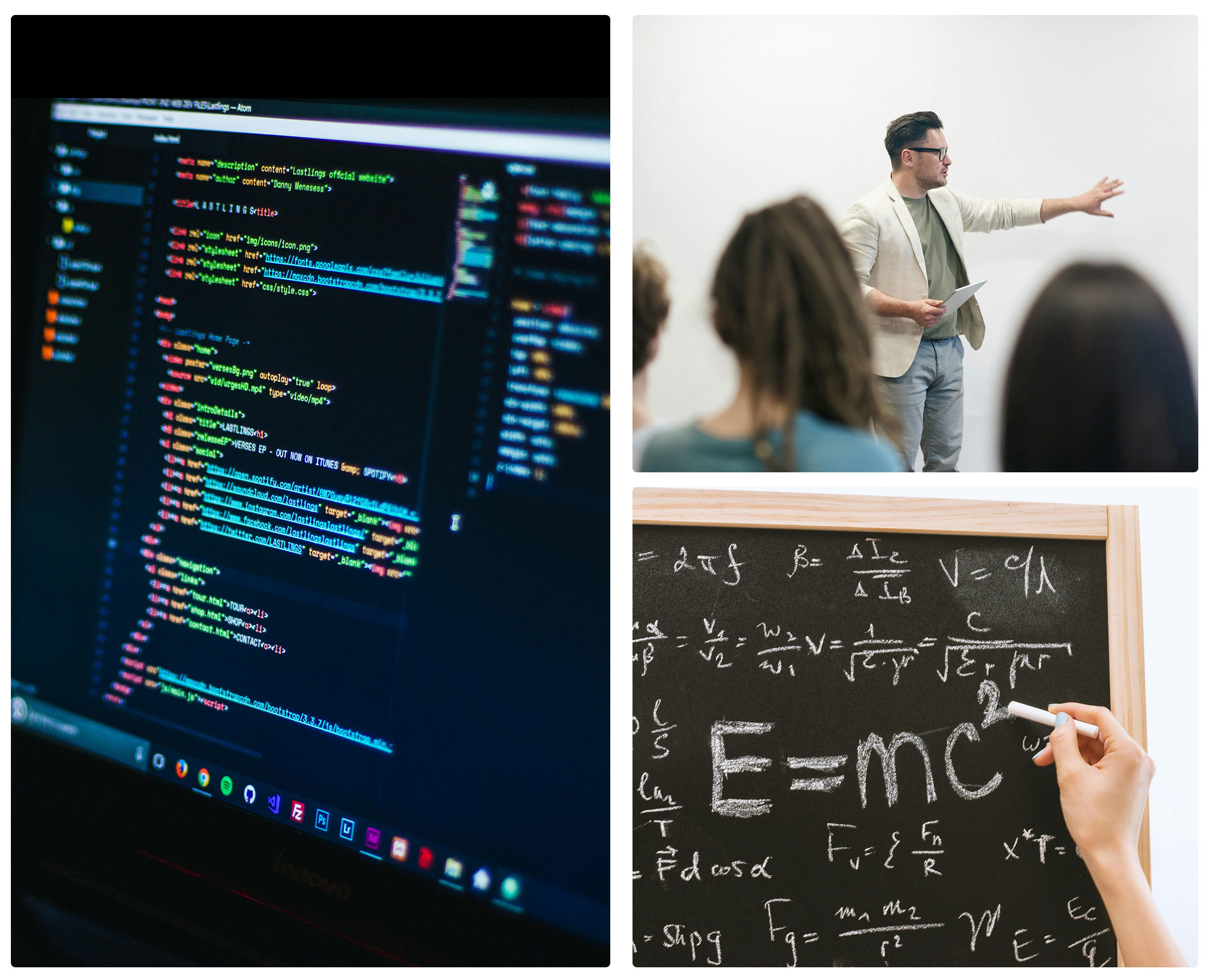

Advantages of JEO Robot Joint Motors in Education

The application of robot joint motors can facilitate the integration of different subjects

Apr 24,2025

As a top joint motor manufacturer, JEO’s motors (robot joint motor, brushless DC motors, servo motors) enhance teaching and expand learning methods for STEM, coding, and more.

Versatile Performance:0.01-50N·m torque, ±0.1mm accuracy: gear motor / rotary actuator for industrial simulations; coreless motors for art/3D printing.

Practical Design:Lightweight ([≤1.2kg] frameless torque motors): 18% less energy, 25% longer runtime.AC motors / synchronous motor: 8+ hour workshops (no overheating).

Cost-Saving Durability:Smart motors / robot joint actuator: 10,000+ hrs lifespan, 35% lower maintenance costs.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

+86 13713219319

Building 2 , No.2, Guanzhang Road, Shijing Section,Dongcheng District , Dongguan City , Guangdong Province.

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home