Unleashing Innovation:JEO Frameless DC Motors Redefine Industry Standards

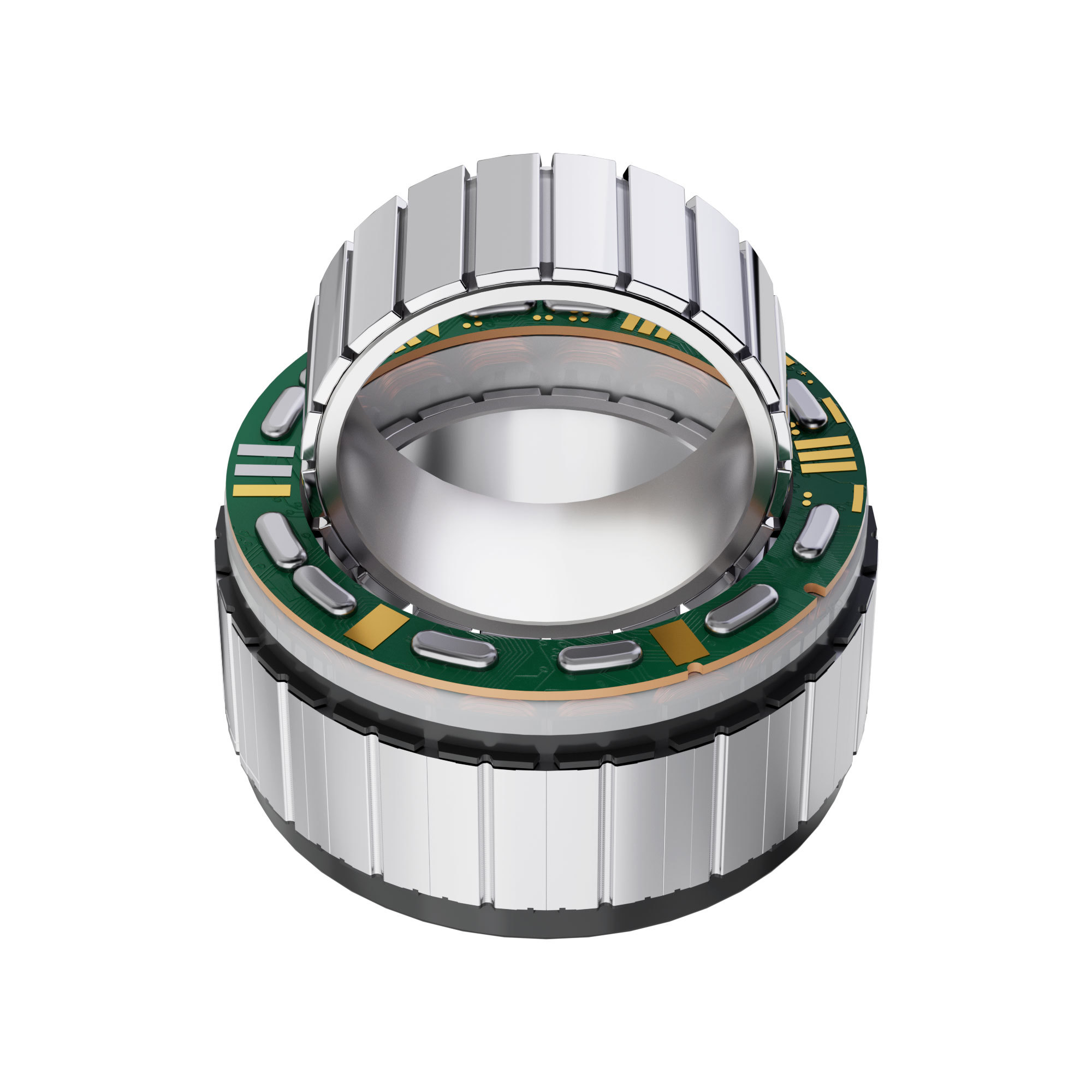

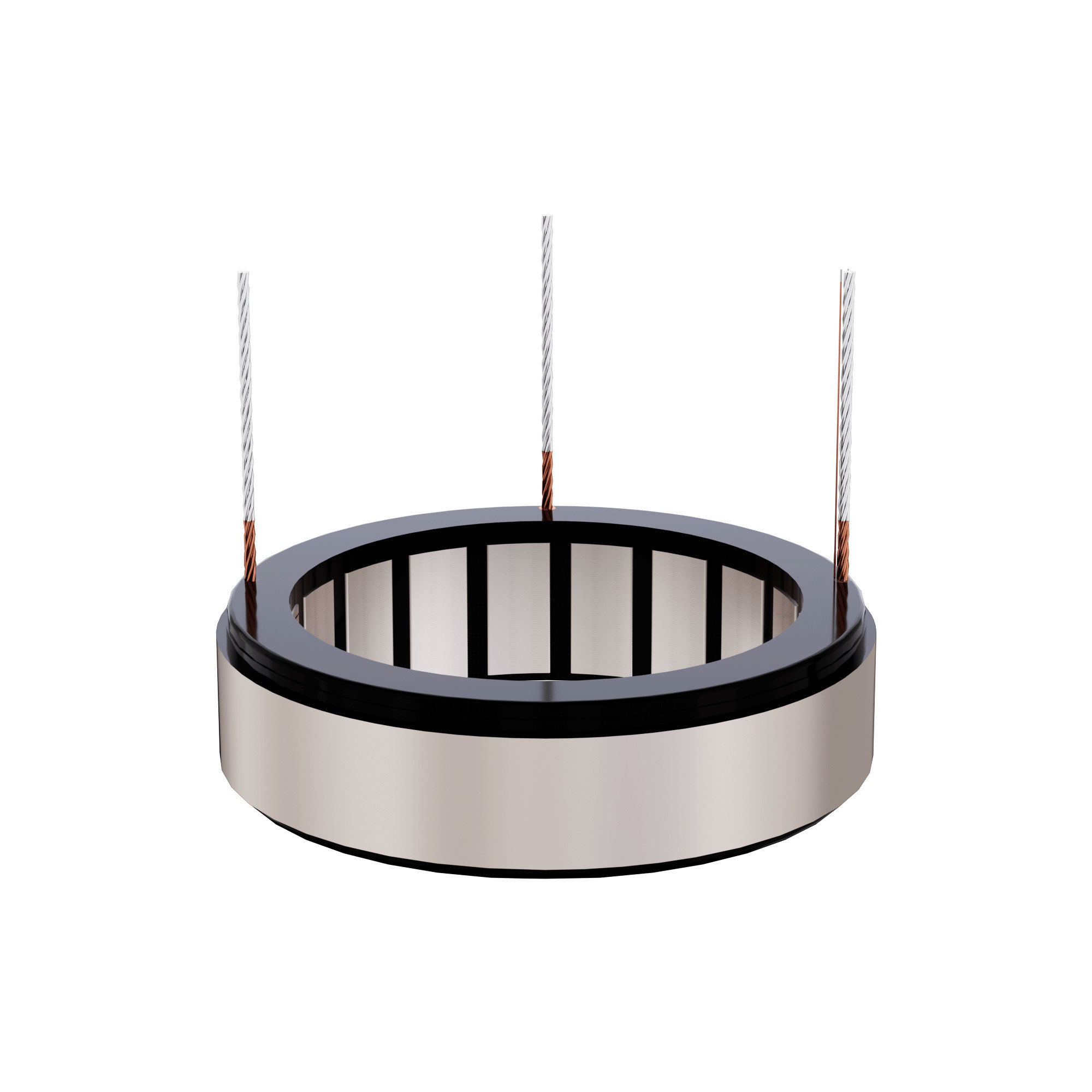

Our Frameless DC Motors aren’t just components; they’re catalysts for progress. In robotics, aerospace, and beyond—from powering humanoid robot joint motor to enabling space exploration—they’re redefining what’s possible. By blending power, precision, and endurance, they meet the tough demands of modern industries, working in tandem with our full portfolio including Brushless DC Motors, Servo Motors, Stepper Motors, and Smart Motors.

Apr 24,2025

Industry Woes: The Motor Dilemma

Across robotics (such as joint motor robot and bionic robot joint motor), aerospace & aviation, and portable gear sectors, conventional motors—including outdated AC motors and basic gear motor designs—face an uphill battle. Balancing lightweight needs (critical for robot joint module motor) with high torque (essential for high torque density robot joint) and long-term sturdiness is a tightrope walk. Excessive eddy current loss causes heat buildup, sapping efficiency of even coreless motor or DC hollow cup motor variants and cutting short service lives. Bulky structures cramp portability for rotary actuator and direct drive linear and rotary motors, limiting where they can be integrated—whether in shoulder joint motor or satellite systems.

Through cutting-edge structural engineering and smart material selection, our frameless DC motors slash weight by [5]% versus traditional models—critical for robot joint actuator and rotary actuator joint module integration. By fine-tuning the magnetic circuit (a technique we also apply to brushless DC motors) and using high-strength, lightweight composites, we keep performance intact while making our motors perfect for cramped, mobile setups—from bionic robot joint motor to portable aerospace gear.

With an optimized copper fill ratio and advanced magnetic design, our frameless torque motors and high-performance robotic actuators deliver top-notch torque density. In tests, they churn out 20% more torque and have [5]% faster response speed than standard servo motors or stepper motors. This makes them ideal for tough, precise jobs—whether powering a high torque density robot joint or a humanoid robot & motor system.

Innovative winding patterns (applied across our DC hollow cup motor and coreless motor lines) and integrated thermal management cut eddy current loss by 5% compared to old designs. Pair that with thermally conductive materials and smart heat-dissipation paths, and our motors—from synchronous motor to direct drive linear and rotary motors—keep heat in check. Heat dissipation gets an 11% boost, ensuring steady running for shoulder joint motor and gear motor applications alike.

Less thermal stress, low eddy current loss, and a tough build (a hallmark of our robot joint module motor and harmonic robot joint actuator) make our motors last way longer. Field tests show they outlast conventional AC motors and basic motor coupler - paired systems by 3x, slashing maintenance costs and total cost of ownership for industries from robotics to space exploration.

Case Study: Powering Humanoid Robotics with JEO Motors

- Short runtimes (due to a heavy, outdated servo motor);

- Insufficient torque for tough terrains (a flaw in its original joint motor design);

- Overheating during long tasks (a common issue with low-quality rotary actuator systems).

Step Into the Future with JEO

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

+86 13713219319

Building 2 , No.2, Guanzhang Road, Shijing Section,Dongcheng District , Dongguan City , Guangdong Province.

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home