Unleashing Innovation: Frameless DC Motors Redefine Industry Standards

High Torque Density & Sensitivity Humanoid Robot Joint Motor

Apr 24,2025

1. Industry Pain: Motor Trade-Offs

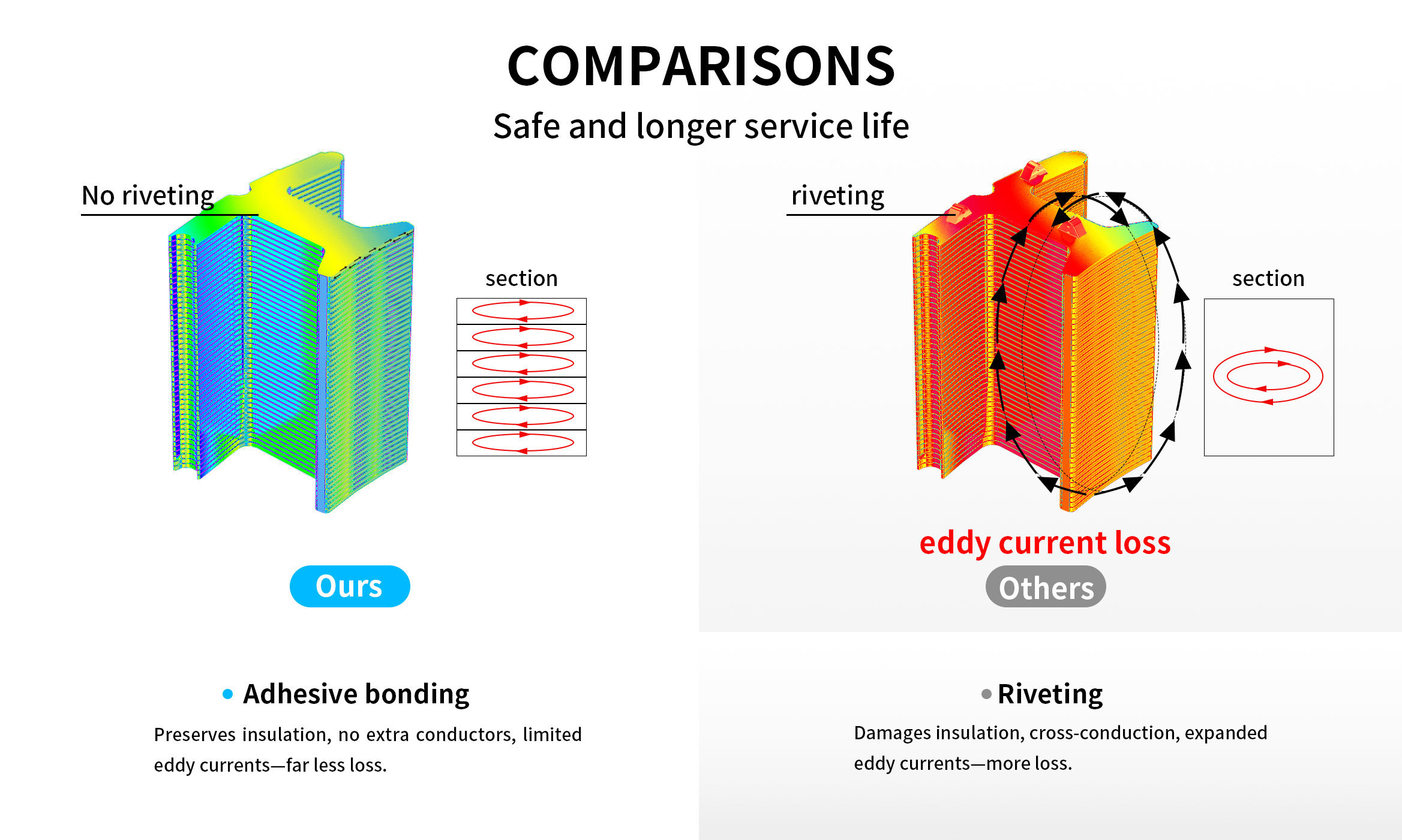

Robotics/aerospace/portable gear face conventional motor limits: poor balance of lightweight, high torque, durability; eddy current loss (heat/inefficiency); bulk crimps portability.

2. Frameless DC Motors: Core Advantages

- Lightweight: [3]% lighter vs traditional (smart materials/magnetic circuit tuning) – fits cramped/mobile setups.

- High Performance: 20% more torque, [6]% faster response (optimized copper fill/magnets) for tough precision tasks.

- Efficient Heat Dissipation Management: 5% lower eddy current loss, 11% better heat dissipation (innovative windings/thermal materials) – steady runtime.

- Durable: 3x longer lifespan (less thermal stress/tough build) – cuts maintenance costs.

3. Case: Humanoid Robotics

- Before: Short runtime, low torque, overheating.

- After: 15% robot weight cut (25% longer runtime), 8% higher payload, no overheating; 3 months non-stop operation, 15% annual maintenance cost reduction.

4. Conclusion

Frameless DC Motors redefine robotics/aerospace/portable gear – blend power/precision/endurance for modern industry demands.

PREVIOUS: