Humanoid Robot Joint Motor Solution for the 2025 Beijing Robot Conference and Future Trends

As the 2025 Beijing Robot Conference approaches, the spotlight on humanoid robot advancements intensifies. Joint motors, the "muscles" of humanoid robots, are pivotal for their mobility and performance. This solution presents a cutting - edge joint motor design, aligning with the conference's focus on innovation and future - proofing robot development.

Apr 24,2025

I. Introduction

II. Joint Motor Design - Drawing from the Bearing Comparison Concept

A. Structural Innovation

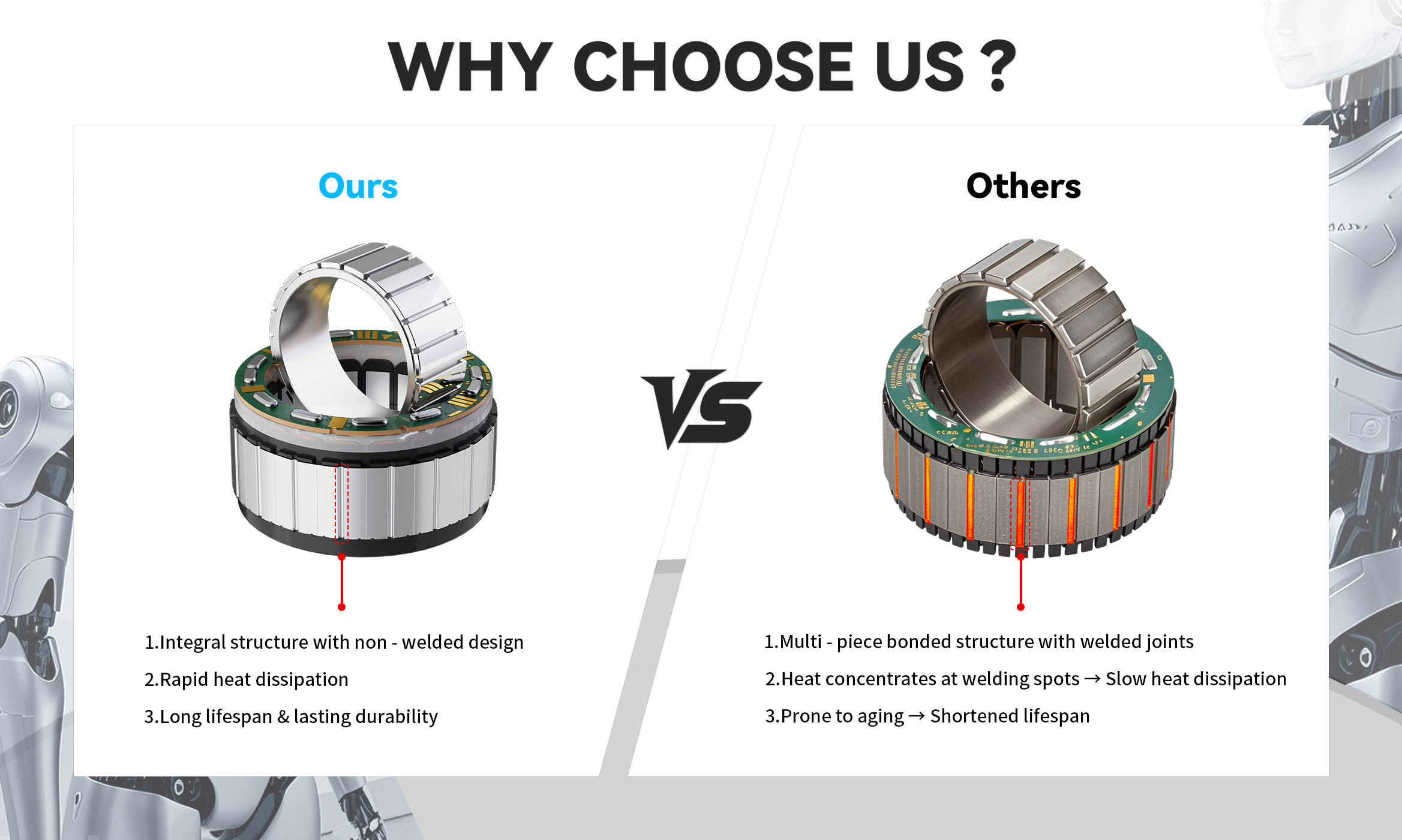

- Integral, Non - welded Structure (Inspired by "Ours" Bearing)

- Our humanoid robot joint motor adopts an integral, non - welded structure. Similar to the superior bearing design shown, this eliminates weak points from welded joints. In the context of humanoid robots, it ensures:

- Enhanced Structural Integrity: Just as the integral bearing resists deformation better, our joint motor's structure can withstand the complex and repetitive forces during robot movements, like walking, arm - raising, and delicate manipulation tasks.

- Consistent Performance: There are no weld - induced stress concentrations that could lead to performance degradation over time. For humanoid robots, this means more stable joint movements, crucial for tasks requiring precision, such as human - robot interaction in service scenarios at the conference.

- Our humanoid robot joint motor adopts an integral, non - welded structure. Similar to the superior bearing design shown, this eliminates weak points from welded joints. In the context of humanoid robots, it ensures:

- Contrast with Conventional Multi - piece, Welded Motors

- Traditional joint motors often use multi - piece, welded structures. As seen in the "Others" bearing comparison, these have:

- Heat Concentration Issues: Welded joints in motors can cause heat to concentrate, similar to the bearing's welding spots. In humanoid robots, this heat buildup can:

- Affect Motor Efficiency: Increased heat leads to energy losses, reducing the robot's operational time. For example, a service robot at the conference may need to operate continuously for demonstrations; heat - related inefficiencies would limit its showcase capabilities.

- Shorten Lifespan: Just as the welded - joint bearing ages faster, these motors are prone to premature failure, increasing maintenance costs and downtime for robot developers.

- Heat Concentration Issues: Welded joints in motors can cause heat to concentrate, similar to the bearing's welding spots. In humanoid robots, this heat buildup can:

- Traditional joint motors often use multi - piece, welded structures. As seen in the "Others" bearing comparison, these have:

B. Thermal Management - Rapid Heat Dissipation

- Efficient Heat Dissipation Design

- Our joint motor incorporates advanced heat - dissipation mechanisms, much like the rapid heat - dissipating bearing. For humanoid robots:

- Sustained Operation: During long - duration tasks at the Beijing Robot Conference, such as multi - hour demonstrations or collaborative work sessions, the motor can maintain optimal operating temperatures. This prevents thermal - induced slowdowns or shutdowns.

- Reliability in Varied Environments: Whether in the conference's indoor exhibition halls or potential future outdoor deployment (e.g., in smart city robot applications), the motor's heat - dissipation ability ensures consistent performance.

- Our joint motor incorporates advanced heat - dissipation mechanisms, much like the rapid heat - dissipating bearing. For humanoid robots:

- Comparison with Conventional Motors

- Motors with poor heat - dissipation, like the slow - dissipating bearing, face:

- Performance Fluctuations: As heat accumulates, the motor's speed and torque output can become unstable. In a humanoid robot, this could lead to jerky movements, undermining the robot's ability to perform smooth and natural - looking actions, which are key for applications like companion robots or advanced industrial humanoid assistants.

- Accelerated Aging: Prolonged exposure to high temperatures accelerates component degradation. In the long run, this not only increases the total cost of robot ownership but also hinders the scalability of humanoid robot deployment in various industries.

- Motors with poor heat - dissipation, like the slow - dissipating bearing, face:

C. Longevity and Durability

- Lifespan and Durability Goals

- Inspired by the long - lifespan bearing, our joint motor is engineered for:

- Long Lifespan: Humanoid robots are expected to have a relatively long service life, especially as they move from conference showcases to real - world applications like healthcare assistance, elder - care, and education. Our motor's design, with its integral structure and efficient heat management, ensures a longer operational lifespan. For example, in a healthcare robot used for patient - lifting and assisting in hospitals post - conference, the long - lasting motor reduces the need for frequent replacements.

- Lasting Durability: It can endure the mechanical stresses of humanoid robot movements, from the high - impact forces of running (in advanced humanoid prototypes) to the gentle but repetitive motions of a robot guide at the conference.

- Inspired by the long - lifespan bearing, our joint motor is engineered for:

III. Alignment with 2025 Beijing Robot Conference Themes

- Innovation Showcase at the Conference

- At the 2025 Beijing Robot Conference, our joint motor - equipped humanoid robots can be center - stage for live demonstrations:

- Dynamic Performances: The motor's integral structure and rapid heat dissipation enable robots to perform complex dance - like movements, showcasing human - like agility. This aligns with the conference's goal of presenting the latest in robotic capabilities to attendees, including industry investors, researchers, and enthusiasts.

- Interactive Experiences: In the context of human - robot interaction zones at the conference, the reliable joint motors ensure that robots can engage in safe and smooth interactions, like handshakes, gesture - based communication, and even light - duty collaborative tasks with conference participants.

- At the 2025 Beijing Robot Conference, our joint motor - equipped humanoid robots can be center - stage for live demonstrations:

- Future - Proofing for the Conference's Vision

- The conference is not just about current achievements but also about shaping the future of robotics. Our joint motor design:

- Supports Scalability: As the robotics industry grows, from small - scale research prototypes to large - scale deployment in service and industrial sectors, our motor's durability and efficiency make it suitable for mass - produced humanoid robots. This aligns with the conference's focus on promoting the commercialization and widespread adoption of robotic technologies.

- Enables Technological Convergence: With the integration of AI, sensors, and advanced control systems in future humanoid robots, our joint motor provides a stable and reliable actuation foundation. For example, in AI - powered companion robots that will be a part of future smart living scenarios, the motor's performance ensures seamless integration of complex behaviors.

- The conference is not just about current achievements but also about shaping the future of robotics. Our joint motor design:

IV. Future Robot Development Trends and Our Motor's Role

A. Trend 1: Increased Human - Like Dexterity and Mobility

- Need for Advanced Joint Motors

- Future humanoid robots will be required to perform more human - like tasks, from 精细 manipulation in manufacturing (e.g., assembling small electronic components) to complex surgical assistance. Our joint motor, with its integral structure and rapid heat dissipation, can provide the precise and powerful actuation needed for these dexterous movements.

- For example, in surgical robots of the future, the motor's stability and precision can enable the robot to perform minimally invasive procedures with sub - millimeter accuracy, a trend that will be further explored and promoted in conferences like the Beijing Robot Conference in the coming years.

- Our Motor's Contribution

- The non - welded, integral structure allows for more compact and efficient joint design, enabling robots to have a more human - like range of motion. As robots need to navigate complex environments, from cluttered factory floors to domestic spaces, our motor's durability ensures reliable operation in these unstructured settings.

B. Trend 2: Energy Efficiency and Sustainability

- The Imperative for Efficient Actuation

- With the growing emphasis on sustainable technology development, future robots must be energy - efficient. Our joint motor's rapid heat dissipation reduces energy losses, similar to how the efficient bearing design saves energy in mechanical systems.

- In humanoid robots used for long - term service, like in smart cities for public assistance, the energy - efficient operation of our joint motor can extend the robot's battery life, reducing the need for frequent recharging and minimizing the environmental impact of energy consumption.

- Our Motor's Advantage

- The long lifespan of our joint motor also contributes to sustainability. Fewer motor replacements mean less electronic waste, aligning with the future trend of eco - friendly robotics development.

C. Trend 3: Integration of Multiple Functionalities

- Complex Robot Systems

- Future humanoid robots will be more than just movement platforms; they will integrate multiple functions such as environmental sensing, communication, and decision - making. Our joint motor's reliable performance provides a stable base for these integrations.

- For example, in a future humanoid robot that serves as a mobile data - collection and communication hub in disaster - stricken areas, our motor's durability ensures that the robot can move to the disaster site, collect data, and communicate with rescue teams effectively, even in harsh conditions.

- Our Motor's Role in Convergence

- As robots become more intelligent and connected, the joint motor's consistent performance is crucial for maintaining the integrity of the robot's overall system. Our motor's design, which avoids the pitfalls of welded - joint failures, ensures that the robot can operate continuously in these complex, multi - functional scenarios.

V. Conclusion